top of page

Once we knew we wanted to explore a continuum robot structure, our first prototype were laser cut ply vertebra actuated with lengths of fishing wire for each of the four axis. This showed surprisingly even actuation in each axis, but with no straightforwards way to evenly secure each vertebrae to the central metal spine.

A handmade aluminium model allowed grub screws to lock the vertebra to the central spine, but the overall weight increase and inconsistencies of hand-fabrication meant single-axis actuation would end up spiralling the whole body.

Off-the-shelf stepper motor mounts used as vertebra reduced inconsistencies in the system, but still proved problematic with the whole body spiralling when a single axis was actuated - indicating a larger issue with this design.

To rule out weight as the system's issue, we 3D printed vertebrae that could be screwed into position on the spine. However the system still wasn't rigid enough for precise single-axis actuation.

A major redesign had the vertebra use a universal-joint mechanism between each neighbour. This drastically improved single axis actuation, but showed compression between layers under heavier loads of actuation.

To mitigate uneven compression between vertebrae, we used rubber bands between each vertebrae's four axes. But this only accentuated the compression issue.

Instead of evenly distributed compression, we used sections of washing-up sponges to install evenly distributed expansion forces. This was the first successfully clean test of single axis actuation, and had the added bonus of an encouragingly tactile form.

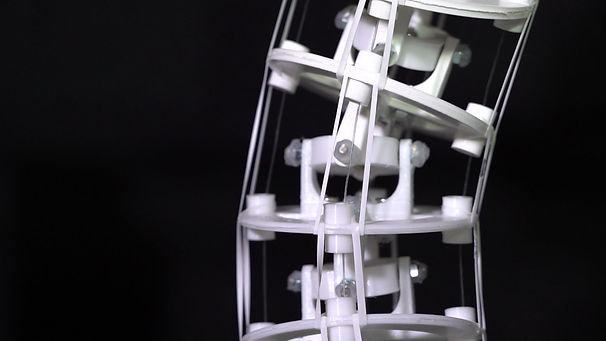

Knowing that we needed even expansion force between each axis of each vertebrae, we used strips of flexible PLA that we printed flat and then bent into place to expand the system. Tinkering with the length and thickness of these home-made "springs" allowed for bespoke control of expansion throughout the system.

(and custom metal springs are really expensive for rapid prototyping)

We managed to fabricate and test all of these prototypes over two weeks to quickly understand the materiality and mechatronics required to design the full robotic body for our installation.

bottom of page